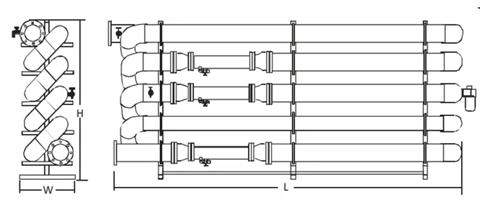

T-FLOC™ FLOCULATION TUBE

T-FLOC™ is InfraCorp’s compact flocculation tube system, designed to provide efficient, controlled floc formation in a small footprint compared to conventional mechanical flocculators. It uses a hydraulic mixing regime to enhance the coagulation–flocculation process, ensuring optimal particle collision and growth without moving parts.

T-FLOC™ is InfraCorp’s compact flocculation tube system, designed to provide efficient, controlled floc formation in a small footprint compared to conventional mechanical flocculators. It uses a hydraulic mixing regime to enhance the coagulation–flocculation process, ensuring optimal particle collision and growth without moving parts.

Theory Of Operation

Tube Flocculator is a unit operation used in WTP and WWTP. The tube flocculator is a plug flow reactor in which processes such as coagulation, flocculator, demulsification, precipitation and pH control can take place under highly controlled and well defined conditions. The mixing action in the floc tube is achieved in the turns, constrictions, and expansions. The restriction and expansion of pipe size causes additional turbulence and numerous eddies in the flow pattern. These eddies, when combined with the changes in flow direction at the elbows, disrupt the velocity gradient and flow patterns, providing significant radial mixing as well as axial back mixing. In addition, some radial and axial mixing is achieved in the straight sections due to the turbulence of the fluid in the pipe. NanoWater T-Floc™ tubes are sized so that flow in the straight sections is well into the turbulent flow regime (NRe>50,000)

Core Technology

T-FLOC™ employs a coiled or serpentine flocculation tube engineered to create uniform turbulence. As water flows through the tube:

- Coagulants and polymers are evenly dispersed.

- Gentle but effective mixing encourages microflocs to grow into dense, settleable flocs.

- The process is fully hydraulic, requiring no mechanical agitators or power.

This makes T-FLOC™ a robust, low-maintenance alternative to traditional flocculation basin

Key Features of T-FLOC™

- No moving parts — minimal maintenance.

- Compact design — reduces civil works and footprint by up to70%.

- High mixing efficiency with optimized retention time.

- Plug-and-play modules — easy to integrate into existing treatment systems.

- Corrosion-resistant materials (HDPE, SS, FRP).

- Designed for coagulation, flocculation, and chemical reaction contact time.

Performance Advantages

|

Parameter |

Conventional Basin |

T-FLOC™ Tube System |

|

Footprint |

Large |

2–4× smaller |

|

Energy Use |

Mechanical mixing required |

None (hydraulic only) |

|

Mixing control |

Variable |

Uniform & stable |

|

Maintenance |

High (moving parts) |

Very low |

|

Installation |

Civil construction |

Modular, rapid install |

T-FLOC™ MODELS

The table below lists the recommended flow ranges and dimensions of standard floc tubes. Alternate configurations can be designed if needed.

Models TF-430 and smaller use Schedule 80 PVC pipe, while larger models use Schedule 40 PVC pipe. Floc tubes for higher temperature flows can be constructed with CPVC piping. Standard frames are constructed from galvanized carbon steel and may be provided in stainless steel if desired. The units come with a standard of three injector ports complete with check valves and shut-off valves. The units can be customized with additional injector and sampling ports and various orientations.

Applications

- Municipal water & wastewater treatment plants.

- Pre-treatment before lamella clarifiers and sedimentation tanks.

- Industrial effluents requiring coagulation–flocculation.

- RO/NF pre-treatment and ZLD polishing steps.

- Decentralized and modular treatment plants.

Technology Integration

T-FLOC™ is designed to seamlessly pair with: