NanoUltra™ ULTRAVIOLET STERILIZER

High-quality Materials for Long Lasting

InfraCorp manufactures Ultraviolet units with the finest 316 Stainless Steel, Electro polished internally as well as externally for years of corrosion free service. The system allows water to come in contact with Ultra Violet rays having 30,000 micro watts second/cm2 UV dosage & 2537 Angstrom (254 nm) units wavelength. The silica quartz jacket provides 100% efficiency due to its pure crystal-clear transparency as compared to the Teflon tubes which has only 25% transparency.

InfraCorp offers a complete range of Ultra Violet Units, for drinking and process water applications with outputs ranging from 100 LPH up to 1,00,000 LPH

HOW DOES UV STERILIZER WORKS ?

Ultraviolet light deactivates the DNA of bacteria, viruses and other pathogens and destroys their ability to multiply and cause disease. Specifically, UV light causes damage to the nucleic acid of microorganisms by forming covalent bonds between certain adjacent bases in the DNA. The formation of such bonds prevents the DNA to reproduce.

Ultraviolet or UV energy is found in the electromagnetic spectrum between visible light and x-rays and can best be described as invisible radiation. In order to kill microorganisms, the UV rays must actually strike the cell. UV energy penetrates the outer cell membrane, passes through the cell body and disrupts its DNA preventing reproduction. UV treatment does not alter water chemically; nothing is being added except energy.

Special low-pressure mercury vapor lamps produce ultraviolet radiation at 254 nm, the optimal wavelength for disinfection and ozone destruction. The UV lamp never contacts the water; it is either housed in a quartz glass sleeve inside the water chamber or mounted external to the water which flows through UV transparent Teflon tubes. Some ultrapure water systems use 185 nm UV units for reducing TOC (total organic carbon).

FEED WATER QUALITY

Water quality plays a major role in the transmission of germicidal UV rays. It is recommended that the water does not exceed following maximum concentration levels.

HOW DOES UV STERILIZER WORKS ?

- Turbidity: 5 Nephelometric turbidity units (N.T.U.)

- Total Suspended Solids: 10 milligrams per liter (mg/L) – maximum

- pH: 6.5 – 9.5

- Color: None

- Hardness: 6 grains per gallon (gpg) or 102 parts per million (ppm)

- Iron: 0.3 milligrams per liter (mg/L) – maximum

- Manganese: 0.05 milligrams per liter (mg/L) – maximum

- Ultraviolet Transmission: 80% through one centimeter – minimum

HOW DOES UV STERILIZER WORKS ?

- Turbidity: 5 Nephelometric turbidity units (N.T.U.)

- Total Suspended Solids: 10 milligrams per liter (mg/L) – maximum

- pH: 6.5 – 9.5

- Color: None

- Hardness: 6 grains per gallon (gpg) or 102 parts per million (ppm)

- Iron: 0.3 milligrams per liter (mg/L) – maximum

- Manganese: 0.05 milligrams per liter (mg/L) – maximum

- Ultraviolet Transmission: 80% through one centimeter – minimum

|

PATHOGENS |

Common Name |

Scientific Name |

3 Log Reduction |

|

Viruses |

Rota |

Rotaviruses (Human) |

32 mJ/cm2 |

|

Infectious Hepatitis |

Hepatitis B |

25 mJ/cm2 |

|

|

Adenovirus |

126 mJ/cm2 |

||

|

ECHO Virus |

Echovirus |

25 mJ/cm2 |

|

|

Bacteria |

Salmonella |

Salmonella Typhimurium |

22 mJ/cm2 |

|

Staph |

Staphylococcus aureus |

3.2 mJ/cm2 (2 log) |

|

|

Strep |

Streptococcus faecalis |

9.8 mJ/cm2 |

SELF CLEANING SYSTEM

Automatic, long-life Viton wipers, powered by a self-contained air compressor, keep the quartz sleeves surrounding the UV lamps clean, ensuring optimum UV output at all times, and wiper frequency is easily adjustable. The system’s ballasts have a variable output between 50-100% and are easily accessible. In addition, the interface of the PLC control system can be customized by the user to suit their requirements. Lamp replacement and other routine maintenance is also straightforward and can usually be carried out by on-site staff.

ULTRA VIOLET UNITS - ADVANTAGE

More effective against viruses than chlorine – Chlorine is becoming less acceptable because of harmful byproducts, handling problems, & risk of overdosing.

· Immediate treatment process, no need for holding tanks, & retention times, so footprint is small.

· Extremely economical due to low capital, operational & maintenance costs.

· No chemicals added to the water supply – resulting in no byproducts & no need for specialized storage requirements

· No change in taste, odor, pH, conductivity of water

· Automatic operation

· Simplicity and ease of maintenance, periodic cleaning, and annual lamp replacement, no moving parts to wear out

· Easy installation, only two water connections and a power connection

· Compatible with any water treatment processes.

InfraCorp’s UV disinfection systems offer a comprehensive range of models tailored to the specific requirements of diverse applications. With industry-leading solutions in both medium- and low-pressure UV lamp technologies, we are able to address site-specific customer needs in the most efficient and straightforward manner

UV light can efficiently reduce microbiological growth in water .UV radiation with wavelength of 254 nanometers kills bacteria , viruses ,and fungi by destroying the DNA of the microorganisms. Disinfection with UV light can be used for nearly all water types without leaving by-products or effecting the tase and quality of the water

We specialize in high-performance, chemical-free water and wastewater treatment solutions utilizing advanced ultraviolet (UV) disinfection and ozone oxidation technologies for effective pathogen and contaminant control

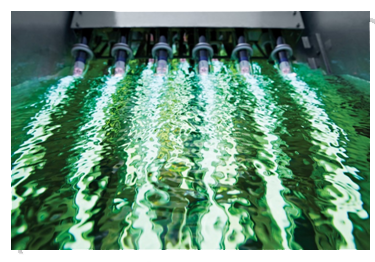

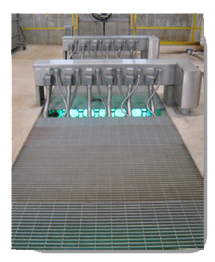

InfraCorp has developed the pre-engineered ChannelStream™ range of channel UV wastewater treatment systems for municipal and industrial wastewater applications. ChannelStream™ is specifically designed for the disinfection of secondary and tertiary effluent across a wide range of flow rates through a scalable, modular design. The system utilizes advanced low-pressure, high-output (LPHO) amalgam UV lamps, delivering stable and consistent UV output throughout an operating life of up to 14,000 hours.

MODULAR DESIGN

The ChannelStream™ flexible, modular design means simple installation and maintenance, making it the ideal open channel UV system for municipalities with low flow requirements. the ChannelStream™ is the first ‘plug-and-play’ open channel UV system available on the market. Installation is straightforward: the unit is simply placed on a flat surface, the inlet and outlet piping is connected, and it is ready to use. The totally self-contained unit negates the need to install lamp wires through conduits or connect chemical feed systems.

APPLICATIONS FOR WASTEWATER

1- Biological Oxygen Demand: 30 milligrams per liter (mg/L) – maximum

2- Total Suspended Solids: 30 milligrams per liter (mg/L) – maximum

3- Ultraviolet Transmission at 254 nanometers: 65% through one centimeter – minimum

InfraCorp is an innovative manufacturer and provider of advanced UV sterilization and disinfection systems for commercial, industrial, and residential applications. With extensive experience in the design, engineering, and manufacture of UV-based treatment solutions, InfraCorp develops cutting-edge technologies, equipment, and methodologies to deliver highly effective, reliable, and safe sterilization processes. Our UV systems are engineered to meet stringent performance and regulatory requirements, ensuring consistent pathogen inactivation while optimizing energy efficiency and operational reliability