NanoSettler™ Lamella Clarifier

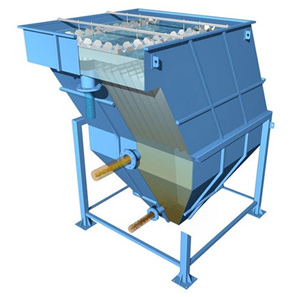

NanoSettler™ is InfraCorp’s advanced lamella clarifier system engineered to deliver high-rate solid–liquid separation in a compact footprint. It leverages inclined plate technology to accelerate settling, making it ideal for both municipal and Industrial Water and Wastewater treatment Applications.

NanoSettler™ Lamella Clarifier

NanoSettler™ is InfraCorp’s advanced lamella clarifier system engineered to deliver high-rate solid–liquid separation in a compact footprint. It leverages inclined plate technology to accelerate settling, making it ideal for both municipal and Industrial Water and Wastewater treatment Applications.

Key Features of NanoSettler™

- High clarification efficiency with a fraction of the space of conventional clarifiers.

- Modular & prefabricated units for rapid installation and scaling.

- Low energy footprint, gravity-driven settling.

- Corrosion-resistant construction options (FRP, SS, HDPE-lined steel).

- Integrated sludge removal system for low maintenance.

- Flexible flow configurations (upflow / crossflow)

Applications

- Pre-treatment in surface water and groundwater plants

- Tertiary polishing in municipal wastewater treatment

- Industrial wastewater (chemical, food & beverage, mining, textiles)

- Brine and RO reject clarification prior to recovery or ZLD

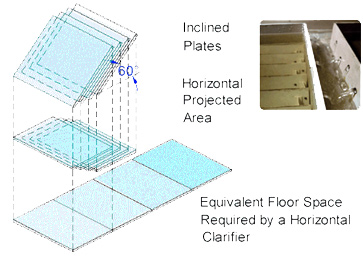

The InfraCorp Lamella Clarifier is designed to provide low cost, efficient solids removal from a wide range of waste and process liquids. The inclined plate and the tube Settler Lamella clarifier design allows the total gravity settling area to be as much as ten times more than the actual floor space occupied by the clarifier.

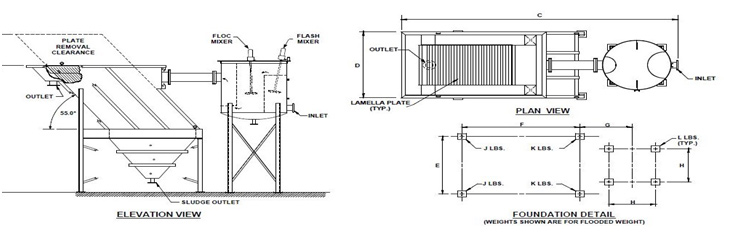

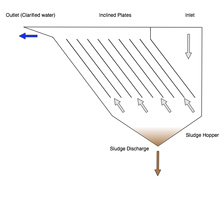

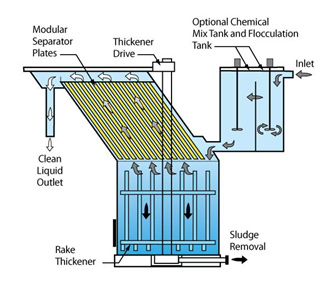

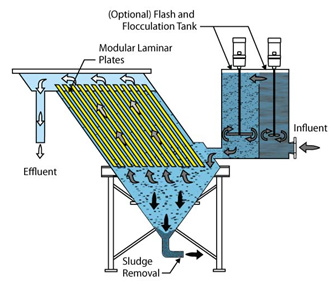

The Flash Mix and Flocculation Tanks (optional) allow for the addition of chemicals and polymers that will aid the settling process — adjusting pH to precipitate dissolved solids and/or enhancing the agglomeration of suspended particles into heavier, more settle-able floc. The liquid is fed from these tanks into the clarifier through the inlet chamber, which directs flow into the separation section.

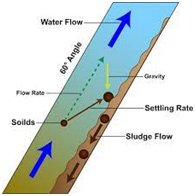

The liquid then enters the lower area of the laminar plates through side slots which distribute it across the entire width of the plates. Particulate settles onto the face of the plates and slides down to the clarifier bottom. The clarified liquid exits the plate sections through weirs at the top of the unit which are designed to develop and control adequate pressure drop, maintaining laminar flow through the plates. The clarified liquid then flows into the effluent chamber and out of the clarifier.

Settled solids collect at the bottom of the pyramid sludge hopper and are removed from the clarifier. A Sludge Thickener (optional) with rake mechanism may be utilized in place of the pyramid hopper when applicable.

Performance Advantages

| Parameter | Conventional Clarifier | NanoSettler™ |

| Footprint | Large | 3–5× smaller |

| Hydraulic Loading Rate | 0.5–1.0 m³/m²·h | Up to 6 m³/m²·h |

| Start-up time | Long | Rapid (plug & play) |

| Settling efficiency | Moderate | High |

| Maintenance | Manual | Automated / minimal |

Process Characteristics

Lamella clarifiers can handle a maximum feed water concentration of 10000 mg/L of grease and 3000 mg/L of solids. Expected separation efficiencies for a typical unit are:

- 90-99% removal of free oils and greases under standard operation conditions.

- 20-40% removal of emulsifiedoils and greases with no chemical amendment.

- 50-99% removal with the addition of chemical agent(s).

- Treated water has a turbidityof around 1-2 NTU.

Technology Integration

NanoSettler™ can be paired seamlessly with other InfraCorp technologies such as:

- Clariflo™ for enhanced coagulation–flocculation

- BioSep™ for biological polishing

- Min™ZLD systems for zero-liquid discharge schemes.

InfraCorpdesign and manufacture two types of lamella sedimentation equipment , according to the different filtration medium used inside a lamella clarifier, the lamella clarifier can be divided into

- Lamella Tube Clarifier (also called Tube Settler)

- Lamella Plate Clarifier(also called Plate Settler)

Both types of equipment use shallow sedimentation theory to achieve the desired results. Use of Tube Settlers, or Plate Settlers can allow for greater loading rates of the system by expanding the surface area for sedimentation. This allows for greater loading rates, and results in a large reduction in the basin size needed to achieve the same results. It is generally accepted a reduction in settling surface area of 80+ percent can be achieved.

Sludge Blowdown System for Clarifiers

This sludge blow-down system is designed to monitor the time the Clarifier is in use, i.e. when the pump that feeds the beginning of the gravity flow waste stream leading to the Clarifier, the timer is timing.

After the predetermined time has elapsed, the controller will automatically open the discharge valve and activate the discharge pump to the sludge thickening Tank, and then automatically turn off the pump and close the valve. System includes: Sludge Valve, air valve and control panel with timers and cast iron diaphragm pump.

Engineering Drawing