Thermal Evaporator

Advanced Thermal Concentration for High-Salinity and Hard-to-Treat (H2T)Waters

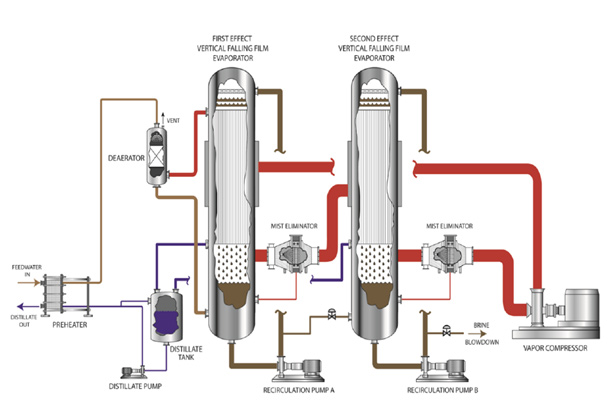

The InfraCorp Evaporator is a high-efficiency thermal evaporation system engineered to recover clean water and minimize brine volumes from saline or industrial wastewater. Designed around InfraCorp’s philosophy of Hard-to-TreatTechnology (H2T™), this process enables reliable concentration of RO reject, process effluent, and high-TDS brines—serving as a critical bridge between membrane treatment and Zero LiquidDischarge (ZLD) crystallization.

evaporator is a core unit operation in thermal water treatment, desalination, and Zero Liquid Discharge (ZLD) systems — designed to remove water by evaporation, thereby concentrating dissolved solids, salts, or contaminants.

It serves as a front-end or complementary stage to crystallizers, brine concentrators, or distillation systems in both industrial and municipal applications.

Core Operating Principles

- Operates under vacuum to lower boiling temperature (reducing energy demand).

- Heat is transferred through tube bundles or plates using steam, waste heat, or mechanical vapor recompression (MVR).

- Often used in multi-effect or forced-circulation configurations for improved efficiency.

What an Evaporator Does

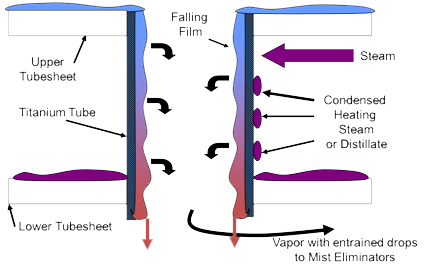

- Heats liquid feed (such as saline water or wastewater) to its boiling point,

- Evaporates water (forming vapor),

- Condenses the vapor into distillate (clean water), and

- Retains concentrated brine or slurry as residue.

In many systems, the goal is to maximize distillate recovery while minimizing energy use and scaling.

Common Types of Evaporators

|

Type |

Description |

Typical Use |

|

Falling Film Evaporator |

Thin film of liquid flows down heated tubes; high efficiency and gentle operation. |

Low-scaling, heat-sensitive feeds. |

|

Forced Circulation Evaporator (FCE) |

Feed is circulated rapidly through heat exchanger to prevent scaling. |

High-TDS or fouling brines. |

|

Multiple-Effect Evaporator (MEE) |

Uses vapor from one effect as heat for the next, reducing energy use. |

Large-scale ZLD or industrial systems. |

|

Mechanical Vapor Recompression (MVR) |

Compresses vapor to reuse latent heat; highly energy-efficient. |

Power plants, RO brine concentration. |

|

Agitated Thin Film Evaporator (ATFE) |

Rotating blades spread liquid as thin film; ideal for viscous or slurry feeds. |

Concentrated sludges or organics. |

Performance Metrics

|

Parameter |

Typical Range |

|

Feed TDS |

30,000–200,000 mg/L |

|

Recovery Rate |

85–95% |

|

Distillate Quality |

<10 µS/cm |

|

Energy Use |

10–25 kWh/m³ (depending on type) |

|

Operating Pressure |

0.05–0.3 bar (vacuum) |

Applications

- Desalination (RO reject minimization)

- Industrial wastewater (power plants, textiles, oil & gas, pharma)

- Chemical and fertilizer industries (acid concentration, product recovery)

- ZLD systems (paired with crystallizers for solids recovery)

Evaporator vs. Brine Concentrator

|

Aspect |

Evaporator |

Brine Concentrator |

|

Purpose |

General water removal / concentration |

Advanced concentration of RO brine to near-saturation |

|

Feed Salinity |

10,000–200,000 mg/L |

70,000–300,000 mg/L |

|

Recovery |

Moderate to high |

Very high |

|

Output |

Concentrate or slurry |

Near-saturated brine or feed for crystallizer |

Turnkey Services – From Concept to Commissioning

At InfraCorp, we provide end-to-end turnkey solutions for evaporation and crystallization systems—managing every phase of your project with precision and expertise. From initial design and engineering to fabrication, installation, commissioning, and after-sales support, we serve as your reliable project partner at every step.

With a proven track record of successful collaborations with international conglomerates, and a dedicated global project management team, we ensure timely delivery, seamless execution, and fully operational systems upon handover.Whether it’s a greenfield installation or system upgrade, our turnkey approach guarantees performance, compliance, and peace of mind.