DioxPro-2™

Advanced Dual-Precursor Chlorine Dioxide Generator Engineered for Precision. Built for Performance. Trusted for Safety.

Technology Overview

The DioxPro-2™ is a next-generation chlorine dioxide generator based on a dual-precursor reaction between acid and sodium chlorite. Developed for industrial and municipal applications, it provides on-site, on-demand generation of ClO₂ with unmatched control, safety, and efficiency.

Why Chlorite Control Matters

When chlorine dioxide is added to water for disinfection, it doesn’t form trihalomethanes (THMs) or haloacetic acids (HAAs) like chlorine or chloramine—but instead, it degrades or reacts to form chlorite and chlorate.

Chlorine dioxide is a powerful and widely used disinfectant in drinking water treatment. However, it leaves behind chlorite ions (ClO₂⁻) as a primary by-product. Elevated chlorite levels can pose health risks, particularly to sensitive populations, and are strictly regulated under EPA, WHO, and EU guidelines.

Typical Industries Served

- Municipal Utilities

- Food & Beverage Processing

- Power Generation

- Petrochemical & Refineries

- Pulp & Paper

- Mining & Metallurgy

Clearion™ | Closed-Loop Chlorite & Chlorate Control with ClO₂ Recovery

Clearion™ is InfraCorp’s proprietary technology that incorporates a gas-phase separation step using vacuum-assisted extraction to remove volatile disinfection byproducts—such as chlorine dioxide (ClO₂) gas—while concentrating non-volatile chlorite and chlorate ions in the liquid waste stream. Within the Clearion™ vacuum contactor, ClO₂ gas and its byproduct ions are selectively separated: the ClO₂ gas is recovered and returned to the main disinfection stream, while the chlorite and chlorate ions are retained in the aqueous phase and reduced downstream via catalytic treatment. This unique, closed-loop system enhances disinfection efficiency, minimizes chemical consumption, and ensures residual oxidants remain safely within regulatory compliance thresholds—preserving the integrity of your water treatment process.

Key Features

- Targeted Chlorite Reduction down to <0.2 mg/L

- Compatible with existing chlorine dioxide systems

- Safe for potable water applications

- Optimized for post-treatment polishing or distribution system control

- Supports compliance with MCL / regulatory thresholds

- Minimizes formation of chlorate during treatment

Why Choose InfraCorp?

InfraCorp’s DioxPro-2™ isn’t just a generator—it’s a complete solution backed by over 20 years of water treatment innovation.

Our Advantages Include:

- Proprietary reactor design for enhanced yield and chemical stability

- ProprietaryClearion™ | Closed-Loop Chlorite & Chlorate Control with ClO₂ Recovery

- ProprietaryClearion™ | Closed-Loop Chlorite & Chlorate Control with ClO₂ Recovery

- Turnkey support from commissioning to maintenance and remote diagnostics

- Sustainable design, reducing chemical usage and environmental footprint

Global service network, ensuring uptime and peace of mind

Key Advantages of the Clearion™ Approach

- Closed-Loop ClO₂ Recovery

Recovers and reuses ClO₂, reducing overall chemical consumption by up to 30%. - Phase-Selective Contactor

Uniquely separates volatile oxidants from ionic byproducts using pressure differential and phase affinity. - High-Efficiency Ion Removal

95% chlorite and >90% chlorate reduction with minimal operational costs.

- No External Scrubbers Required

Built-in gas recovery eliminates need for exhaust neutralization systems. - Retrofit-Ready

Designed for integration with existing ClO₂ systems in water, wastewater, and industrial treatment plants.

DioxPro-2™Generation Chemistry

The DioxPro-2™model generatesthe chlorine dioxide in two methods

- Diluted precursors chemical (DioxPro-2D™)

- Concentration precursors (DioxPro-2C™ )

General chemical reaction methods for either models (DioxPro-2D™ orDioxPro-2C™)are :

Method No.1 :

The sodium chlorite–hydrochloric acid method

5 NaClO2 + 4 HCl → 5 NaCl + 4 ClO2 + 2 H2O

Acid-chlorite 2-chemical chlorine dioxide generators represent the highest quality, performance and accuracy available in 2-chemicals chlorine dioxide generators

Method No.2 :

The chlorite–sulfuric acid method:

4 ClO−2 + 2 H2SO4 → 2 ClO2 + HClO3 + 2 SO2−4 + H2O + HCl

Method No.3 :

The chlorite persulfate method:

2 NaClO2 + Na2S2O8 → 2 ClO2 + 2 Na2SO4

The concentration of chlorine dioxide produced by these methods varies between 1 and 3 g/L.

DioxPro-2D™Generators

TheDioxPro-2D™ chlorine dioxide generator is designed to produce and consistently maintain a product yield greater than 95%, which makes it ideal for drinking water treatment.

The DioxPro-2D™ generators and range in capacity from 40-800 g/hr (2.4 – 42.4 lb/day). These chlorine dioxide generators are ideal for applications with low water flow and therefore small ClO2 dose and reactant chemical consumption.

This method of generation Utilizes the following precursors

- Nanocide -DC (7.5% sodium chlorite)

- Nanocide -DA (9% hydrochloric acid)

These chlorine dioxide generators are ideal for applications with low water flow and therefore small ClO2 dose and reactant chemical consumption.

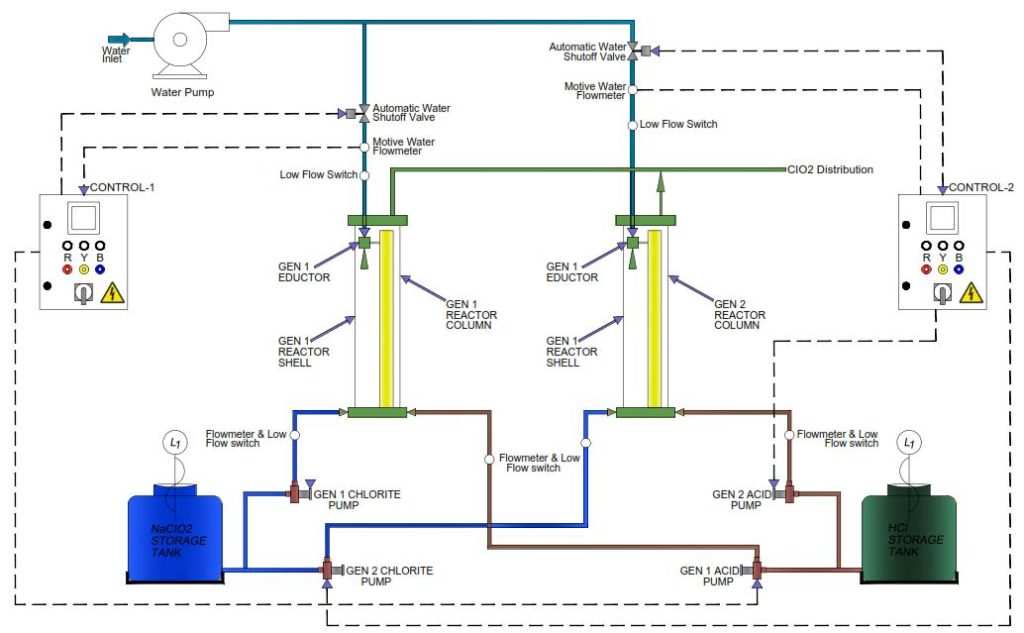

DioxPro-2C™ Generators

The DioxPro-2C™ generators utilizes the following chemical precursors

– Nanocide-CC (31% sodium chlorite)

– Nanocide-CA (33% hydrochloric acid )

– Water dilution

The range of capacity from 150-10,000 g/hr (7.9 – lb/day).

Feed System :

- DioxPro-2C™Vacuum or submerged

DioxPro-2C™ Redundance Vacuum or submerged feed system

Superior Yield. Lower Operating Cost. Proven Performance.

Chlorine dioxide generation performance varies significantly by technology, directly impacting chemical consumption, operating cost, and overall system value.

Traditional acid–chlorite generators typically achieve chlorite yields of 65–68%, with even lower overall conversion efficiency due to unreacted acid. While this approach remains a cost-effective and simple solution for low-capacity applications, its chemical efficiency is inherently limited.

For customers seeking higher efficiency, reduced chemical usage, and improved lifecycle economics, advanced generation technologies deliver clear advantages. Electrochemical and three-chemical generator systems provide substantially higher conversion rates and product purity.

The InfraCorp Electrochemical RiteDos™ generator sets a new benchmark in performance, producing chlorine dioxide at 95–99% purity with greater than 80% chlorite conversion. Because only a single chemical precursor is required, this high chlorite conversion translates directly into exceptional overall efficiency and predictable operating costs.

Similarly, the chlorine–chlorite process can achieve conversion efficiencies of up to 95%, depending on reaction pH and reactant concentrations, making it an excellent choice for applications demanding maximum yield and chemical efficiency.

Municipal Applications

- Drinking Water

- Iron and Manganese Control

- Taste and Odor Control

- Wastewater Treatment

Industrial Applications

- Cooling Water Disinfection

- Process Water

- Legionella Control

- Food & Beverage Industry

- Dairy, Poultry & Swine

- Bleaching Processes (pulp & paper)

Oil & Gas Applications

- Hydraulic Fracturing

- Bacteria Sterilization

- Brackish Water Treatment

- Sulfite& Iron Removal

- Scale Inhibitor

- H2S Scavenger

Technology Key Value Propositions

- Superior Efficacy

Kills pathogens and biofilms more reliably than chlorine or UV. - Fewer Harmful Byproducts

No trihalomethanes (THMs) or chloramines – aligns with tightening regulations. - Lower Dose, Higher Impact

Lower chemical usage = reduced OPEX and fewer safety incidents. - Scalable Across Sectors

Municipal, industrial, agriculture, cooling towers, oil & gas, food processing.

Sustainability Advantage

Enables compliance with ESG and water reuse standards.

Revolutionizing NanoFlow™ Reactor | Proprietary High-Efficiency Mixing Technology

The NanoFlow™ Reactor is a proprietary chemical mixing system developed by InfraCorp’sengineering team to deliver maximum chemical efficiency, superior process control, and unmatched operational safety. Designed specifically for high-performance chlorine dioxide generation, this submerged, water-flushed reactor ensures precise mixing and reaction kinetics with the lowest possible chemical consumption.

Constructed from food-safe PVDF or corrosion-resistant Titanium, the NanoFlow™ Reactor is engineered for long-term durability in the most demanding industrial and municipal environments. Its fully enclosed, submerged design minimizes gas exposure risks and enhances safety, making it one of the safest and most robust reactors on the market

- Built Entirely from 100% resistant to chlorine dioxide, chlorides, and acids. This ensures unmatched corrosion resistance and long operational life.

- Dual-Chamber Design – The inner reactor is submerged in an outer dilution chamber. Any potential gas leak is immediately captured, diluted, and flushed into the process stream.

- Fail-Safe Operation – As long as dilution water is flowing, there’s zero risk of gas leakage into the plant room—eliminating one of the most critical hazards in chemical handling.

- Market Advantage – This patented design delivers superior safety, regulatory compliance, and peace of mind for industrial users—creating a clear competitiveedge in hazardous chemical environments.

InfraCorp’s proprietary design isn’t just innovative—it’s mission-critical infrastructure for industries where safety and reliability are non-negotiable

DioxPro-2Vac™ | Smart, Safe, Scalable ClO₂ Generation

InfraCorp’s DioxPro-2Vac™ is a next-generation chlorine dioxide generator engineered for cost-effective, high-safetyperformance in industrial and municipal applications.

- Vacuum-Driven Safety

Operates under vacuum using a precision ProcessEductor, eliminating pressure-related risks and ensuring safe ClO₂ handling. - Efficient Inline Dosing

Generates a stable 500–3000 ppm chlorine dioxidesolution directly into process water—no additional dilution or mixing steps required. - Modular & Intelligent

Scalable from 1 kg/hr and up, with optional:- Booster pumps

- Batch tanks

- Injection pumps

- Automated manifolds for flow pacing or residualcontrol

- Market Advantage

Combines automated control, low maintenance, and superior safety, giving us a competitive edge in both developed and emerging water treatment markets.

DioxPro-2Vac™ is built for global scale, offering utilities and industries a smarter, safer alternative to traditional chlorine systems—with lower lifecycle costs and higher reliability.

InfraCorp is the trusted partner of choice for businesses seeking advanced chlorine dioxide (ClO₂) dosing solutions. Backed by cutting-edge technology and deep industry expertise, we specialize in delivering high-performance ClO₂ systems that meet the most demanding water treatment and disinfection requirements.

From municipal utilities to complex industrial operations, InfraCorp is continuously innovating—developing proprietary technologies that purify water, eliminate contaminants, and enhanceprocess safety and efficiency. Our team of skilled engineers and project managers works closely with each client to design and deliver tailor-made solutions that align perfectly with operational needs.WithInfraCorp, you can trust that your ClO₂ system is built using the latest, most reliable technology on the market.

Contact us today to learn how InfraCorp can support your disinfection goals with proven, sustainable chlorine dioxide solutions.