ClariPro™ Clarifiers with Lamella Settlers

Efficient Clarification and Polishing for Water and Wastewater Treatment

ClariPro™ – Integrated Coagulation, Flocculation & Lamella Settling Unit

ClariPro™ is a modular clarification system that integrates chemical coagulation, mechanical flocculation, and counter-current lamella settling in a single compact structure. Designed for scalable deployment, ClariPro™ effectively treats a wide range of influent qualities with high solids loading and variable flow rates. The unit ensures enhanced particle removal, reduced sludge volume, and consistent effluent clarity, making it suitable for pre-treatment or polishing in water and wastewater treatment systems.

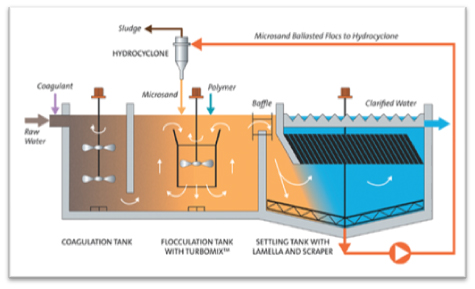

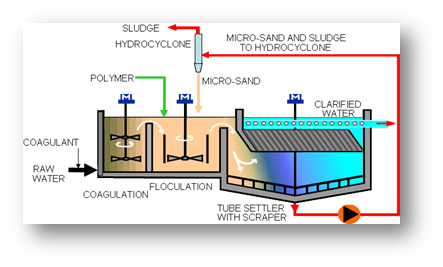

Process Description

The ClariPro™ process is designed to deliver rapid, high-efficiency solids separation by combining the following core stages:

1. Coagulation & Flocculation

Raw water enters the system and is first dosed with inorganic coagulants (e.g., alum, ferric chloride) in a coagulation basin, where initial microfloc formation begins.In the subsequent flocculation basin, polyacrylamide polymer and micro-sand are introduced. The polymer promotes bridging between microflocs, while the micro-sand serves as a ballast agent, enhancing the density and size of the flocs.

2. Lamella Plate Sedimentation

The flocculated water flows upward through an array of inclined lamella plates within the sedimentation tank. The dense, sand-weighted flocs rapidly settle onto the plates under gravity, separating efficiently from the water.

- Clarified water flows upward and is collected via weirs.

- Settled sludge, rich in suspended solids, is captured below.

3. Sand Recovery & Sludge Handling

The settled material is continuously pumped from the bottom of the clarifier to a hydrocyclone, which separates the micro-sand from the sludge.

- Recovered micro-sand is recycled back into the flocculation basin.

- Separated sludge is discharged for further dewatering or disposal.

Recirculation pumps transfer the settled material to the hydrocyclones to separate the micro-sand from the sludge and return it to the flocculation tank. The sludge is discharged to waste.

ClariPro™ – Typical Effluent Water Quality

| Parameter | Typical Effluent Range | Remarks |

| Turbidity | < 1 – 5 NTU | Often <1 NTU with optimized coagulation/flocculation |

| Total Suspended Solids (TSS) | < 10 – 20 mg/L | Can be <10 mg/L in stable operation |

| Biochemical Oxygen Demand (BOD) | 10 – 20% reduction | Some BOD removed with particulate-bound organics |

| Color | Up to 90% removal | Especially effective with ferric- or alum-based coagulants |

| Oil & Grease (O&G) | < 5 – 10 mg/L (with pre-treatment) | With upstream coalescer or surfactant conditioning |

| Phosphates | < 1 mg/L (with dosing) | With chemical precipitation as part of coagulation |

| Heavy Metals (particulate-bound) | Significant reduction | Depends on binding to suspended solids |

Key Features

- Integrated coagulation, flocculation, and lamella settling in one unit

- Compact design with a footprint 10 to 20 times smaller than conventional settlers

- Large effective settling area thanks to inclined lamella plates

- Advanced chemical dosing with optimized control systems

- Modular units for easy scalability and side-by-side installation

- Simple installation, operation, and maintenance

Applications

- Surface water clarification

- Wastewater tertiary treatment

- Industrial process water pre-treatment

- Desalination pretreatment (SWRO/NF systems)

- Cooling tower blowdown or reuse systems

Benefits of ClariPro™

- High throughput with compact footprint

- Superior clarification in high-turbidity or variable-quality feedwater

- Quick start-up and response time

- Reduced chemical and sludge volumes compared to conventional clarifiers

- Easy integration with downstream filtration or membrane systems

ClariPro™ Value Proposition

ClariPro™ delivers high-performance water clarification in a compact, all-in-one solution. By integrating coagulation, flocculation, and lamella settling into a single unit, ClariPro™ reduces footprint, accelerates treatment, and lowers both capital and operating costs. Its modular, scalable design ensures seamless adaptability to a wide range of water qualities and treatment capacities — from decentralized installations to full-scale municipal and industrial plants.

With ClariPro™, clients gain:

- Reliable clarity and compliance — even under challenging influent conditions

- Rapid deployment with minimal civil works

- Operational simplicity and low maintenance

- Versatility for use across multiple industries and water sources

ClariPro™ transforms conventional clarification into a smarter, more compact, and more efficient process.

InfraCorp specializes in tailored water treatment solutions to meet the specific needs of our clients. We support municipal and industrial projects, remediation, food and beverage, water reuse, agriculture, power & utilities, breweries, mining, oil & gas, hotels and resorts as well as pharmaceutical industry.From conceptual design to technical O&M support, InfraCorp extensive experience offers value to our customers.InfraCorp commitment to innovation and applications of advanced technologies as well as the quality of execution.