BioSep™ | Intelligent Biology. Extreme Performance Advanced biological treatment

BioSep™ Process Description

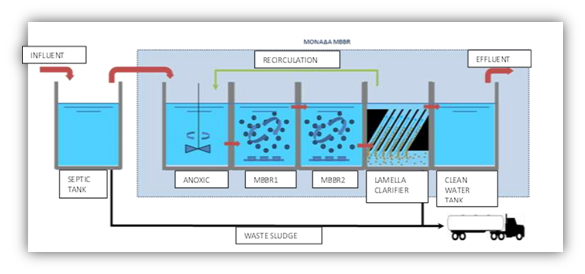

BioSep™ is InfraCorp’s advanced biological treatment system built on the Moving Bed BiofilmReactor (MBBR) platform, optimized for hard-to-treat industrial and municipal wastewater. At the core of the BioSep™ system is InfraCorp’s proprietary NanoChip™ media, engineered toprovide an ultra-high surface area for robust biofilm development and accelerated biodegradation rates. These carriers enable high microbial density, improving process resilience and treatment efficiency. The BioSep™ reactor resembles a conventional activated sludge aeration basin but operates withsignificantly improved kinetics and process stability. In aerobic applications, a fine-bubble diffusedaeration system ensures optimal oxygen transfer and maintains the NanoChip™ media in suspension.

In anoxic or anaerobic configurations, mechanical mixers keep the media in motion to promote consistent contact between the wastewater and biofilm. This continuous mixing action supports optimal microbial activity, even under variable loading conditions, making BioSep™ a compact, modular, and scalable solution for complex wastewater treatment challenges.

Why Choose BioSep™?

- Engineered for Complexity

Handles high organic loading, toxicity, salinity, and shock events with ease. - Powered by NanoChip™

InfraCorp’s proprietary media boosts biofilm density and treatment speed. - Compact & Scalable

Modular design enables fast deployment, retrofitting, or phased expansion. - Lower Lifecycle Costs

Reduced energy consumption, minimal sludge generation, and low maintenance. - Future-Ready

Easily integrates with advanced treatment and water reuse systems.

Process Overview

BioSep™ is InfraCorp’s next-generation biological treatment solution, specifically engineered for high-strength, variable, and hard-to-treat wastewater. Built on a robust MBBR (Moving Bed Biofilm Reactor) architecture and enhanced with NanoChip™—InfraCorp’s proprietary high-surface-area biofilm carrier—BioSep™ offers unmatched treatment performance, scalability, and durability across a wide range of industrial and municipal applications.

At the heart of the system, NanoChip™ media promotes dense biofilm formation and rapid biodegradation, allowing BioSep™ to handle fluctuating loads and recalcitrant organics with ease. The treatment process is housed in a reactor tank similar to a conventional activated sludge aeration basin, yet delivers superior efficiency and footprint reduction.

- In aerobic mode, a fine-bubble diffused aeration system delivers oxygen while keeping NanoChip™ carriers in dynamic suspension.

- In anoxic or anaerobic configurations, mechanical mixers maintain continuous circulation, ensuring high-contact efficiency between wastewater and biofilm.

This continuous motion and high-reactivity biofilm environment enable BioSep™ to achieve high-rate BOD/COD reduction, enhanced nitrification-denitrification, and exceptional system stability—even under shock loads or varying influent conditions.

Key Advantages of BioSep™

- Powered by NanoChip™: Ultra-high surface area for intensified microbial activity

- Modular Design: Scalable for retrofit orgreenfield installations

- Compact Footprint: Higher performance in less space than conventional systems

- Operational Resilience: Handles toxicity, loading

- Sustainable Treatment: Energy-efficient and adaptable to reuse schemes

Why MBBR?

The MBBR engineers at InfraCop focus on minimizing the following elements:

- Energy and operating cost: MBBR systems have optimal energy efficiency, resulting in lower operational costs.

- Reactor volume and HRT: Aeration’s MBBR systems have low hydraulic retention time (HRT), which enables MBBR to operate effectively in smaller reactors.

- Control complexity: Since MBBR systems use a biological treatment process, microorganisms are responsible for the majority of the treatment. As a result, the system requires less operator attention and intervention, making operation simple.

- Footprint: An MBBR system uses biofilm carriers, which provide substantial surface area for microbial growth. The additional mass of microorganisms offers more treatment capacity in a relatively smaller footprint.

- Treatment efficiency: An MBBR offers better treatment efficiency than other types of wastewater treatment systems at lower space and budget requirements.

- Hydraulic capacity: MBBR systems can handle more water at a given time than other systems, enhancing overall efficiency.

- Volumetric efficiency: With bacteria managing much of the treatment process, the parts in an MBBR system can stay in better condition. As a result, the system optimizes the amount of water flowing through the pumps.

- Process life span: The biofilm, NanoChip™ mediacarriers that hold an MBBR system’s bacteria have a long-life expectancy. In turn, the system’s process lifespan also increases.

BioSep™ Process Description

- Up to 13× higher removal rates than conventional carriers

- 5,500 m²/m³ effective surface area for intensive microbial activity

- Enhanced oxygen/substrate diffusion for deep biofilm penetration

- Durable virgin PE construction for long service life and chemical resistance

- Optimized for MBBR and IFAS systems in industrial and municipal settings

NanoChip™ is the driving force behind InfraCorp’s advanced treatment platforms, including BioSep™ and H2T™-branded solutions, enabling world-class biological performance in a compact, scalable format.

BioSep™ Value Proposition High-Performance Biological Treatment for Hard-to-Treat Wastewater

BioSep™, developed by InfraCorp under the H2T™ | Hard-to-Treat Technology platform, delivers a next-generation biological treatment solution engineered for the world’s most challenging wastewater streams. Whether dealing with high-strength industrial effluent, toxic organics, variable loading, or regulatory pressure, BioSep™ offers unmatched reliability, efficiency, and adaptability in a compact footprint.

At the core of BioSep™ is NanoChip™, InfraCorp’s proprietary high-surface-area biofilm media, which accelerates microbial activity and enables exceptional treatment kinetics. BioSep™ outperforms conventional systems in BOD/COD removal, nutrient reduction, and process stability, making it the ideal solution for clients seeking to upgrade existing infrastructure or deploy scalable greenfield treatment.

NanoChip™ MBBR Media│High-Performance Biofilm Carriers by InfraCorp

NanoChip™ is InfraCorp’s proprietary MBBR carrier media, engineered from virginpolyethylene (PE) to deliver exceptional performance in biological wastewater treatment applications. Designed specifically for high-rate Moving Bed Biofilm Reactor (MBBR) systems, NanoChip™ outperforms conventional media with removal rates up to 13 times higher, making it ideal for treating complex and high-load effluents.

Each NanoChip™ provides a protected active surface area of approximately 5,500 m²/m³, enabling dense microbial colonization and efficient biofilm development. The unique geometry and porosity of the chip ensure deep substrate and oxygen diffusion, allowing biofilms to thrive up to 0.5 mm depth on both sides of each chip.

This design results in:

- Extremely high BOD/COD and nutrient removal rates

- Stable and resilient biological performance under variable conditions

- Protection of active biomass from hydraulic shear and toxic shocks

The pore system of NanoChip™ remains continuously filled with active biomass, providing a consistently reactive environment that enhances biological conversion and process stability, even in challenging applications.

Traditional MBBR (Moving Bed Biofilm Reactor) is a proven method for biological wastewater treatment, but InfraCorp has reengineered and elevated this foundation to meet the demands of modern industrial and municipal wastewater challenges.InfraCorp specializes in tailored water treatment solutions to meet the specific needs of our clients. We support municipal and industrial projects, remediation, food and beverage, water reuse, agriculture, power & utilities, breweries, mining, oil & gas, hotels and resorts as well as pharmaceutical industry.From conceptual design to technical O&M support, InfraCorp extensive experience offers value to our customers.InfraCorp commitment to innovation and applications of advanced technologies as well as the quality of execution.