Water and Wastewater Treatment Plant upgrade

Water and Wastewater Treatment Plant upgrade

Objectives of Expansion

When upgrading a plant using BioFix™ technology, the main goals are typically to:

- Increase treatment capacity (flow and load) without new tanks.

- Improve nitrification/denitrification for nutrient removal.

- Enhance resilience to shock loads and temperature fluctuations.

- Optimize footprint and costs compared to full expansion.

Benefits of IFAS Expansion

|

Category |

Advantages |

|

Capacity |

30–50% increase in organic/nutrient load capacity without new tanks. |

|

Performance |

Improved nitrification and denitrification stability. |

|

Footprint |

Minimal additional land required. |

|

Cost |

Lower CAPEX and OPEX compared to new construction. |

|

Flexibility |

Easy retrofit to existing basins with modular installation. |

Wastewater treatment plant upgrade

Because Expanding a wastewater treatment plant (WWTP) using BioFix™proprietary technology of InfraCorp which is efficient and cost-effective way to increase treatment capacity and improve effluent quality without requiring major civil expansion. Below is a detailed explanation of how IFAS can be applied to expand capacity, including design principles, benefits, and implementation steps.

Overview of IFAS Technology

BioFix™ is a hybrid biological treatment process that combines:

- Suspended growth (activated sludge) microorganisms in the aeration basin, and

- Attached growth (biofilm) microorganisms on fixed media or carriers.

By introducing media with a high surface area into existing aeration tanks, you can significantly increase the biological solids retentiontime (SRT) and biomass concentration — which allows higher organic and nutrient removal capacity in the same volume.

Expanding WWTP capacity using BioFix™ technology is a proven,efficient, and flexible solution that leverages existing infrastructure. It is especially effective where:

- Land availability is limited,

- Strict effluent nitrogen limits apply, or

- The plant needs capacity growth with minimal downtime.

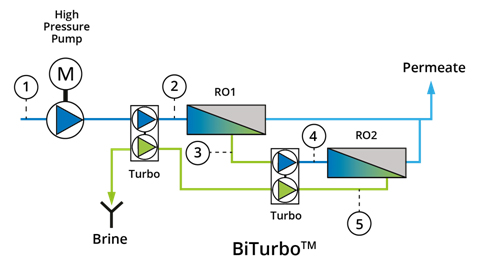

Upgrading an SWRO (seawater reverse osmosis) plant

U[grading SWRO plant involves enhancing its core components to improve efficiency, capacity, and sustainability. Key upgrades include modernizing pretreatment with improved coagulation or carbon capture, retrofitting with more efficient energy recovery devices (ERDs) and pumps, and replacing or upgrading reverse osmosis membranes and vessels. The planning and preparation phase is crucial for analyzing the current design, coordinating stakeholders, and achieving project goals within budget.

Areas for upgrading

- Pretreatment: Modernize the intake, pretreatment, and filtration systems to improve particle removal and reduce the need for chemicals like antiscalants and acids. A key strategy is capturing CO2from power plant flue gas and using it to improve coagulation and acidification, which increases recovery rates and reduces chemical costs.

- Reverse Osmosis (RO) process: Upgrade the RO trains by replacing or installing new membranes, pressure vessels, and piping. Advanced technologies likesystems can increase recovery rates up to 65% by using turbochargers to boost pressure. Adding stage can also significantly improve energy efficiency and water recovery.

- Energy Recovery: Replace older or less efficient energy recovery equipment with state-of-the-art devices to significantly reduce the plant’s energy consumption.

- Post-treatment: Improve post-treatment systems, which can involve modifications to chemical dosing equipment, remineralization, and control systems.

- Control systems: Upgrade the Programmable Logic Controller (PLC) control systems for better plant operation and integration of new components.

InfraCorp comprehensive know-how within the water and wastewater sectors gives us unrivalled forecasting abilities that help optimize investment, bring cost and service level benefits, and maximize asset longevity and value. We have led implementations around the world, and have developed roadmaps on how to improve the asset management of water and wastewater systems through changing processes, developing staff and investing in technology.