H2T™ | Hard-to-Treat Technology

Engineered for Complexity. Proven for Results.

H2T™ is our dedicated platform for solving the most challenging industrial water and wastewater streams.

Whether it’s high-salinity brines, refractory organics, PFAS, toxic loads, or high-COD industrial effluents, H2T™ delivers proven, engineered solutions where conventional technologies fail.

From compliance to water reuse to zero liquid discharge (ZLD), our integrated technologies — including biological (BioSep™), advanced oxidation (DioxPro™), electrochemical, and membrane systems — help industries turn complex wastewater liabilities into sustainable

Typical Problem Waters We Solve:

- High Salinity / TDS

- Refractory Organics (Dyes, Phenols, PFAS, APIs)

- High COD / BOD / Toxic Loads

- Heavy Metals (As, Hg, Cr, Pb, Cd)

- Oils, Grease, Emulsions

- Surfactants, Solvents, Process Chemicals

- Contaminants , Mercaptans , toxic gases

H2T™ | Hard-to-Treat Technology by InfraCorp

Solving Industry’s Most Challenging Water Problems.

When water is more than just dirty — when it’s chemically complex, toxic, or resistant to conventional treatment — InfraCorp delivers with H2T™. At InfraCorp, we specialize in tackling the most difficult and complex industrial water challenges.

Our Hard-to-Treat Technology platform brings together the most advanced solutions, engineered specifically for industries facing the toughest wastewater challenges. From high-salinity brines to persistent organics, we make the impossible practical.

H2T™ = Technology + Expertise + Outcomes.

Our Technology Toolbox

Integrated. Modular. Proven.

We deploy customized treatment trains using best-in-class, advanced technologies.

Each solution is engineered for performance, reliability, and lifecycle value.

Our Core Capabilities Include:

- Advanced Oxidation (AOP, Ozone, Peroxone, UV-H₂O₂)

- High-Performance Membrane Systems (UF / NF / RO / Ceramic)

- Electrochemical & Electrocoagulation Systems

- Biological Treatment (MBBR / BioSep™ with NanoChip™ Technology)

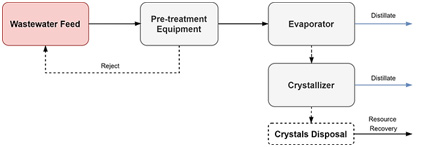

- Zero Liquid Discharge (ZLD) / Crystallization

- Selective Adsorbents / Ion Exchange / Resin Technologies

- Activated Carbon, Media Filtration, and Polishing Units

About H₂T™

Engineered for Complexity. Proven for Results.

H2T™ | Hard-to-Treat Technology by InfraCorp / NanoWater specializes in one thing: making complex, contaminated, and industrially challenging water treatable.

Where conventional treatment technologies fail, H2T™ succeeds.

From high-strength organics and toxic metals to refractory compounds and saline brines, H2T™ delivers targeted, integrated solutions to help industries achieve compliance, reduce risk, and unlock value through water reuse and sustainability.

What is H2T™?

H2T™ (Hard-to-Treat Technology) is InfraCorp’s dedicated technology platform designed specifically for the world’s most complex, contaminated, and difficult industrial water streams.

Where conventional solutions fail, H2T™ succeeds.

What We Solve

Specializing in the Most Challenging Water Streams:

- High COD / BOD Industrial Wastewaters

- Toxic and Refractory Organics (Phenols, PFAS, APIs)

- High TDS Brines / Concentrates

- Heavy Metals (As, Hg, Cr, Pb, Cd)

- Oils, Greases, Surfactants, and Emulsions

- Complex Chemical Mixtures / Hazardous Wastewaters

- Landfill Leachate & Specialty Industrial Effluents

- Gas Extraction Technologies

What Makes H2T™ Different?

- Engineered for Extremes — Capable of handling the most toxic, variable, and concentrated wastewaters.

- Integrated Approach — Combining BioSep™ biological treatment, Ozonic™ AOP, DioxPro™ disinfection, advanced membranes, and Min™ZLD crystallization.

- Field-Proven Performance — Across the harshest industries and environments.

Sustainable Outcomes — Compliance, water reuse, resource recovery, zero liquid discharge (ZLD).

H2T™ Delivers Advanced Solutions Through Integrated Technologies:

- BioSep™ with NanoChip™: Enhanced Biological Treatment for High COD

- DioxPro™ AOP Systems: Advanced Oxidation for Refractory Organics & PFAS

- Min™ZLD: Zero Liquid Discharge & Brine Concentration

- Electrochemical Treatment: Electrocoagulation, Electro-oxidation

- Advanced Membranes: UF, NF, RO, Ceramic for Complex Separation

- Selective Adsorption / Ion Exchange: Metals, Organics, Polishing

- Specialty Chemical Programs:RiteDos™, SalTech™, SeaVolt™

The H2T™ Advantage:

- Compliance Made Certain — Meet even the strictest discharge and reuse regulations.

- Operational Risk Reduced — Protect your assets, people, and reputation.

- Water Reuse Enabled — Turn wastewater into a recoverable resource.

- ESG Targets Delivered — Reduce water footprint, energy use, and environmental impact.

Because Not All Water Can Be Treated by Conventional Means. We are Solving What Others Can’t. Delivering What Industry Needs.

At InfraCorp / NanoWater, we understand these realities because we’ve built our reputation solving them.

H2T™ | Hard-to-Treat Technology is our answer.

InfraCorp | H2T™ Treatment Philosophy

H2T™ (Hard-to-Treat Technology) represents InfraCorp’s integrated approach to tackling the world’s most challenging industrial water streams.

Our philosophy combines multi-barrier treatment design, advanced materials, and process hybridization to transform complex effluents into reusable or discharge-compliant water.

InfraCorp’s H2T™ platform leverages:

- Advanced Oxidation & Catalytic Ozonation – Destroys refractory and volatile organics, including PFAS, phenols, and mercaptans.

- Hybrid Biological-Membrane Systems (BioSep™, MBBR, MBR) – Biologically degrades soluble organics while enhancing solids separation and resilience.

- High-Pressure & Hybrid RO Platforms (HyRO™, HCRO™, XtremeRO™) – Achieves high water recovery from saline or toxic streams.

- Selective Ion& Metal Removal – Integrates nanofiltration, electrochemical reduction, and sorptive media for heavy metal and TDS control.

- Thermal & ZLD Integration (ThermoRO™, Min™ZLD, ZLDx™) – Maximizes water reuse and minimizes brine discharge.

- Gas-Phase Treatment &Odor Control – Neutralizes volatile and sulfurous compounds for worker and environmental safety.

Result: A modular, scalable, and sustainable treatment architecture that enables industries to Reclaim, Reuse, and Recover—even from the hardest-to-treat waters.

Common Characteristics of Hard-to-Treat (H2T™) Industrial Water Streams

-

- High COD/BOD:

Elevated chemical and biological oxygen demand caused by complex organic loads and limited biodegradability. - Refractory Organics:

Persistent and recalcitrant compounds such as phenols, dyes, surfactants, pharmaceuticals, pesticides, PFAS, and other emerging contaminants that resist conventional treatment. - High TDS / Salinity:

Excessive levels of dissolved salts, brines, and minerals—typical in desalination reject, chemical, and mining effluents—leading to scaling and osmotic stress in membranes. - Toxic Heavy Metals:

Presence of hazardous metals including arsenic, mercury, chromium, lead, cadmium, nickel, and copper that require selective removal, immobilization, or reduction. - Oil, Grease & Stable Emulsions:

Hydrocarbon-rich or emulsified wastewaters common in petrochemical, refinery, automotive, and food industries that demand physicochemical or electrochemical separation. - Surfactants, Solvents & Industrial Chemicals:

Complex mixtures of cleaning agents, degreasers, and process solvents that cause foaming, membrane fouling, and inhibition of biological systems. - Volatile & Odorous Compounds:

Inclusion of mercaptans, sulfides, ammonia, and volatile organic compounds (VOCs) that release toxic or malodorous gases, posing both safety and environmental concerns. - Extreme pH, Temperature & Toxicity:

Streams with high acidity, alkalinity, or temperature, often coupled with toxic inhibitors, requiring robust materials and process resilience.

- High COD/BOD:

How to Approach Such Projects (Best Practices)

-

- Detailed Characterization: Full water chemistry, flow variability, treatability studies.

- Pilot Testing: Prove technologies in combination on real water.

- Modular, Staged Solutions: Allow adjustment and optimization.

- Lifecycle Cost Analysis: Not just CapEx; consider OpEx, energy, consumables

Hard-to-Treat Complex streams comes from Industrial Water Streams generated from industrial processes that contain a combination of contaminants that make conventional treatment methods insufficient or ineffective. Such streams often require advanced, multi-step treatment strategies and customized solutions.Our Hard-to-Treat Technology platform brings together the most advanced solutions, engineered specifically for industries facing the toughest wastewater challenges. From high-salinity brines to persistent organics, we make the impossible practical