Crystallization: Turning Waste into Value™

Crystallization is a solid-liquid separation process where a solid forms from a homogeneous solution. It’s widely used in water treatment, chemical manufacturing, pharmaceuticals, and mineral recovery. Here’s a focused breakdown of the concept, especially in the context of Zero Liquid Discharge (ZLD) and critical minerals recovery, which InfraCorp is involved in.

Crystallization is the process by which a solid (crystal) forms from a solution when the solute concentration exceeds its solubility under specific temperature and pressure conditions.

Crystallization: A Key Process in ZLD & Resource Recovery

Crystallization is a solid-liquid separation process where a solid phase (crystal) forms from a homogeneous solution as the solute concentration reaches supersaturation. It is a thermodynamically driven process and a critical final step in Zero Liquid Discharge (ZLD) systems and mineral recovery applications.

Crystallization isn’t just the final step — it’s the first step to value creation.

At InfraCorp, our crystallizer-integrated ZLD systems convert complex industrial waste into reusable solids, pure water, and recoverable resources.

Applications in Water & Wastewater Treatment

-

- Zero Liquid Discharge (ZLD) Systems

- Crystallization is used in the final stage of ZLD systems.

- After reverse osmosis and evaporation, the remaining brine is processed in a crystallizer to extract solid salts, leaving no liquid waste.

- Crystallizers can be:

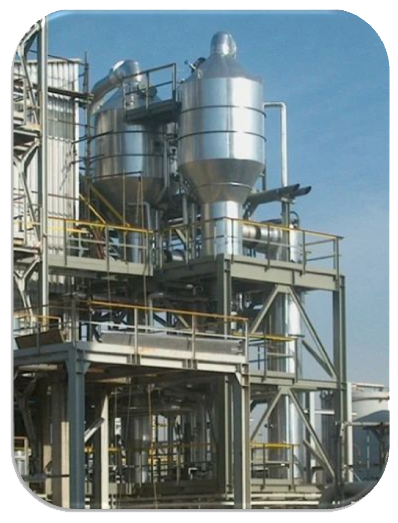

- Forced Circulation Crystallizers (FCC)

- Vacuum Crystallizers

- Draft Tube Baffle (DTB) Crystallizers

-

- Brine Management

- Converts high-salinity brine into usable salts or safe solids for disposal.

- Reduces environmental impact and landfill requirements.

Benefits of Crystallization

- Resource recovery (salts, minerals, metals)

- Enables true ZLD

- Reduces disposal costs

- Minimizes environmental footprint

- Improves regulatory compliance

At InfraCorp, our crystallizers leverage the power of crystallization technology to address the unique needs of various industries—offering innovative solutions that drive efficiency and quality in crystallization processes.

We design advanced systems that enable:

- High product purity and recovery

- Optimized energy and water use

- Reliable and scalable operations

Through a combination of deep process knowledge and cutting-edge engineering, we deliver custom crystallizationsolutionsthat reduce waste and maximize value from complex streams, supporting both sustainability and performance.

Turnkey Services – From Concept to Commissioning

At InfraCorp, we provide end-to-end turnkey solutions for evaporation and crystallization systems—managing every phase of your project with precision and expertise. From initial design and engineering to fabrication, installation, commissioning, and after-sales support, we serve as your reliable project partner at every step.

With a proven track record of successful collaborations with international conglomerates, and a dedicated global project management team, we ensure timely delivery, seamless execution, and fully operational systems upon handover.

Whether it’s a greenfield installation or system upgrade, our turnkey approach guarantees performance, compliance, and peace of mind.